Novakinetics

Our Services

Novakinetics offers a full range of composite manufacturing services, from engineering and design*, testing and qualification, to volume production. All our work is conducted to aerospace standards, with documented work instructions, materials traceability, and comprehensive final inspections before product is delivered to our clients.

*Novakinetics engineering and design services are independent of our AS9100 manufacturing quality system.

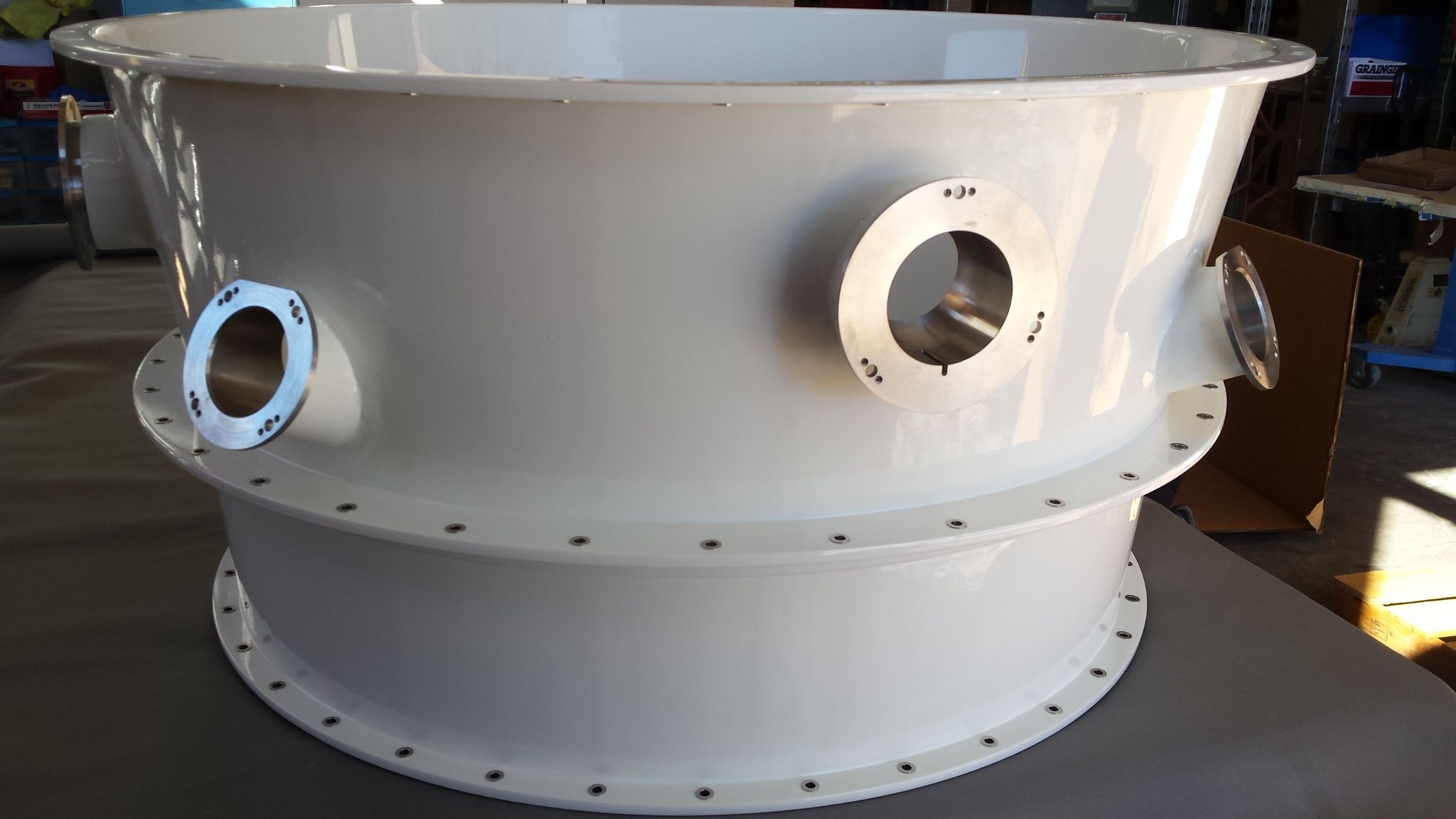

Composites Production

Engineering and Design*

Novakinetics provides engineering and design* assistance from an engineering team that has many years of hands-on experience with the art of composites. We start with your design requirements and optimize for strength, stiffness, light weight, cost, or an appropriate mixture of those properties. Our favorite tools include Solidworks modeling, 2D CAD, and 3D printing, as well as foam-and-fiberglass mockups.

*Novakinetics engineering and design services are independent of our AS9100 manufacturing quality system.

Tooling

Testing and Qualification

Our Products

Prepreg Advanced Composites

Wet Layup Fiberglass

Cool Seats

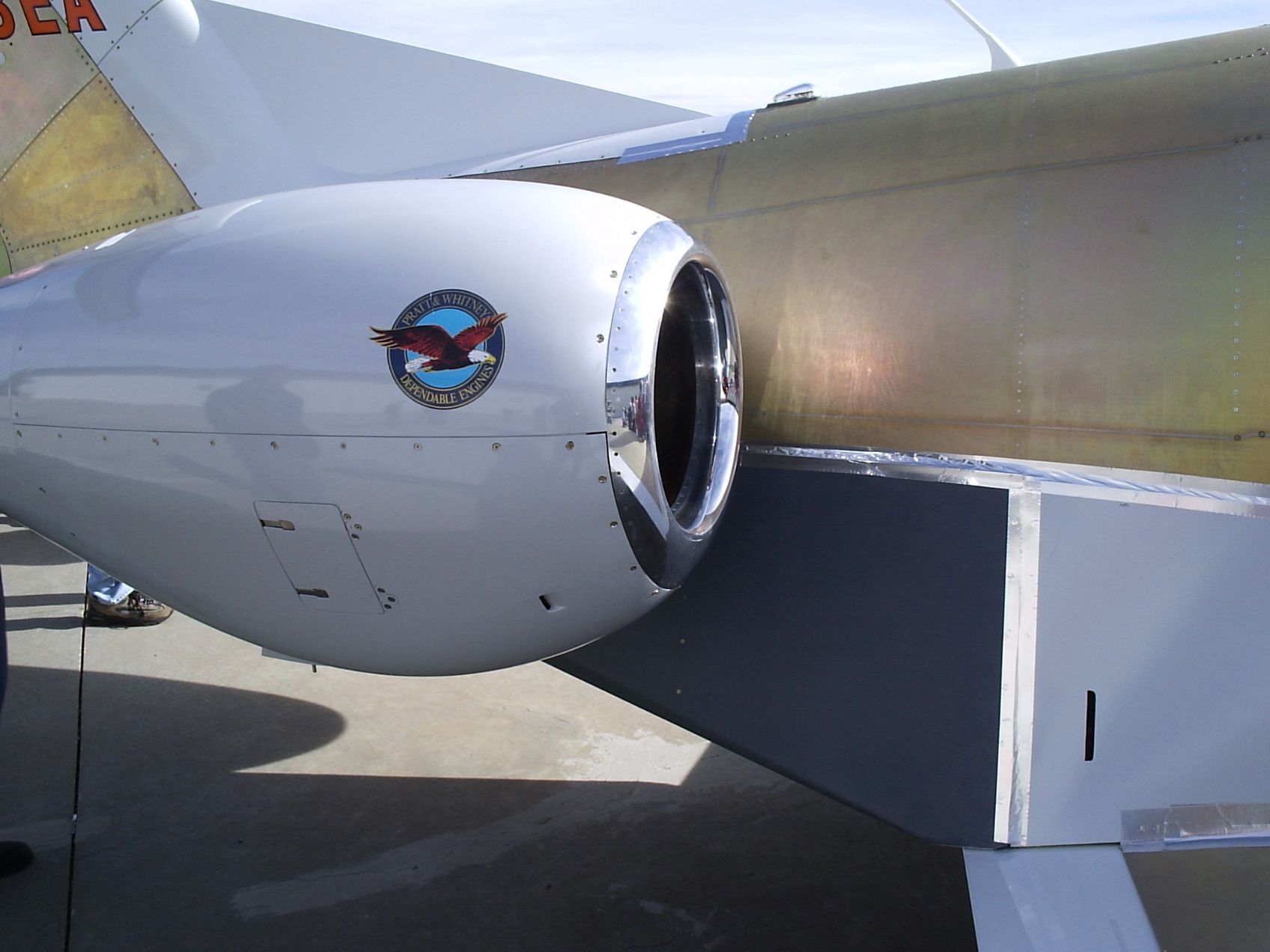

Projects

Here are some of our more significant projects: